China Rapid Prototyping Factory: Unlocking Innovation and Manufacturing Excellence in Metal Fabrication

In today's competitive manufacturing landscape, the importance of rapid prototyping cannot be overstated. It serves as the backbone of innovation, enabling businesses to transform their ideas into tangible prototypes swiftly and efficiently. Among the numerous global players, China rapid prototyping factory hubs have emerged as industry leaders, integrating advanced technologies, cost-effective solutions, and unparalleled manufacturing expertise to propel industries forward. Specifically, companies like deepmould.net exemplify this transformation through their specialization in metal fabricators and rapid prototyping services.

The Evolution of Rapid Prototyping in China’s Manufacturing Sector

China’s rapid development as a manufacturing powerhouse is closely linked to its advancements in rapid prototyping technology. Historically known for mass production, Chinese factories have progressively shifted towards precision manufacturing, customizations, and innovative prototyping solutions. This evolution is driven by the need for faster product development cycles, reduced time-to-market, and the ability to iterate designs rapidly.

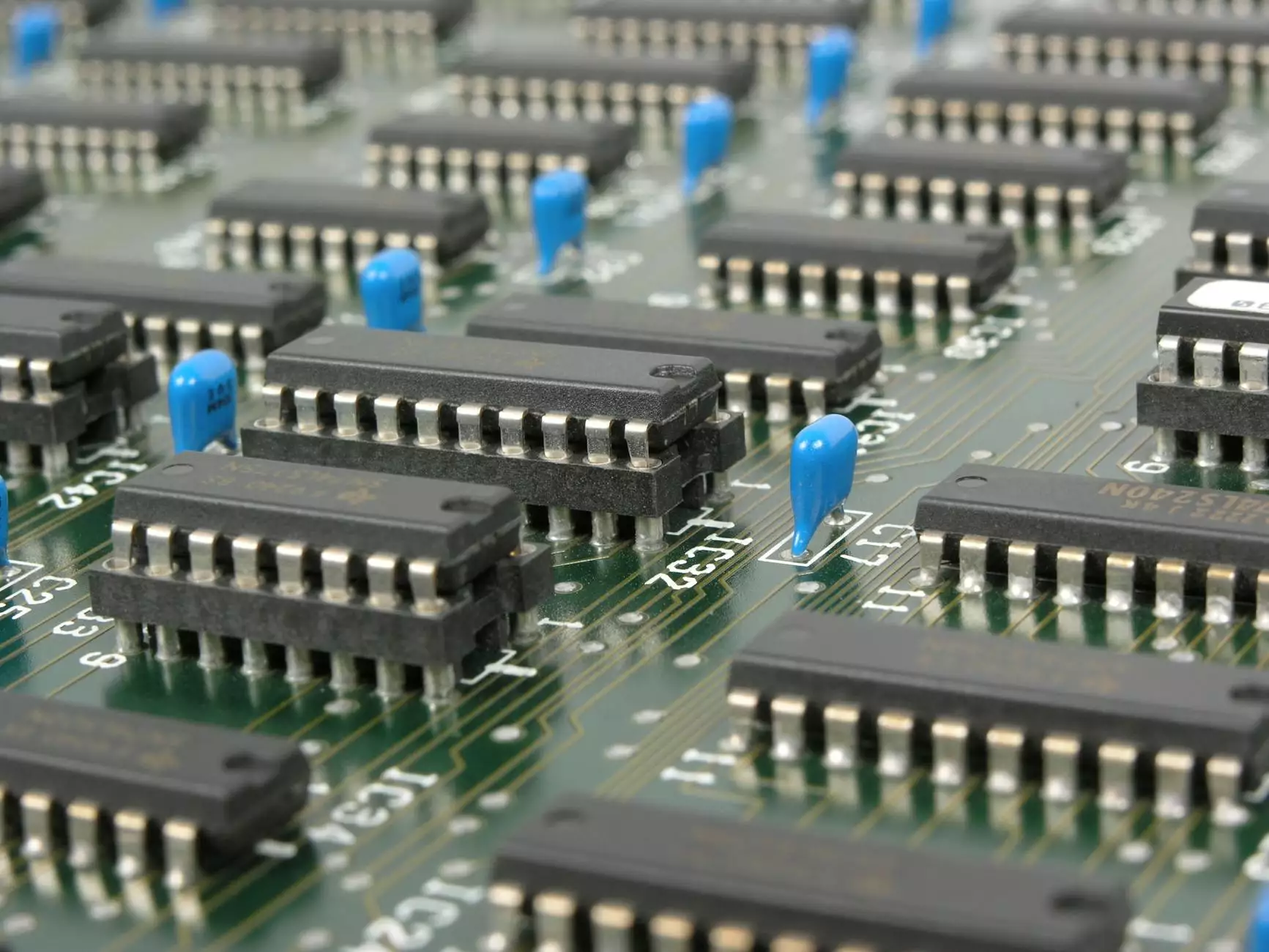

The china rapid prototyping factory landscape now features cutting-edge techniques such as 3D printing, CNC machining, metal laser sintering, and investment casting. These processes allow for high-fidelity prototypes with superior material properties, essential for industries such as aerospace, automotive, electronics, and industrial equipment.

Key Features and Advantages of China Rapid Prototyping Factory

1. Advanced Manufacturing Technologies

- Selective Laser Sintering (SLS): Producing durable, complex metal parts with high precision.

- CNC Machining: Achieving tight tolerances and fine surface finishes for critical components.

- Metal 3D Printing: Creating complex geometries not feasible with traditional methods.

- Investment Casting: Ideal for large batch runs with consistent quality.

2. Cost-Effective Solutions without Compromising Quality

China’s manufacturing ecosystem allows rapid prototyping factories to offer competitive pricing, making prototype development accessible for startups and multinational corporations alike. This affordability is achieved through optimized supply chains, bulk material procurement, and manufacturing economies of scale.

3. Shortened Lead Times

By leveraging advanced equipment and experienced engineers, these factories significantly reduce turnaround times—from initial design to functional prototype—enabling rapid iteration and quick decision-making.

4. Customization and Flexibility

Flexibility in design modifications and small batch manufacturing allows clients to test multiple versions of their products efficiently. This adaptability accelerates innovation cycles and supports rapid market entry.

DeepMould.net: A Premier China Rapid Prototyping Factory Specializing in Metal Fabricators

As a leading china rapid prototyping factory, deepmould.net has carved a niche in delivering cutting-edge metal fabricators solutions. Their commitment to quality, precision, and customer satisfaction positions them as a trusted partner in the manufacturing sector.

Expertise in Metal Fabrication Technologies

deepmould.net specializes in a broad spectrum of metal fabrication processes, including:

- Precision CNC Machining: Ensuring high accuracy for complex metal components.

- Metal 3D Printing: Utilizing direct metal laser melting (DMLM) for intricate, lightweight parts.

- Laser Cutting and Welding: Providing seamless, high-quality cuts and joints for custom projects.

- Surface Treatment: Enhancing corrosion resistance and aesthetic appeal with anodizing, plating, and polishing.

Industries Served by DeepMould.net

- Aerospace: Manufacturing lightweight, durable parts with high precision.

- Automotive: Producing prototypes and small-batch parts for testing and development.

- Electronics: Creating metal enclosures and components with complex geometries.

- Industrial Equipment: Fabricating robust, high-performance parts for demanding environments.

The Process Flow of a Typical China Rapid Prototyping Factory for Metal Fabricators

Stage 1: Concept and Design

Clients commence with CAD models or sketches. The factory’s engineering team reviews, refines, and validates the design, ensuring manufacturability and cost-efficiency.

Stage 2: Material Selection

Choosing the proper metal materials is crucial. Options include aluminum alloys, stainless steel, titanium, and more, each selected based on strength requirements, weight considerations, and environmental factors.

Stage 3: Prototype Manufacturing

Using state-of-the-art equipment, the factory fabricates the prototype, adhering to precise specifications. Quality control measures are implemented throughout to maintain high standards.

Stage 4: Testing and Iteration

The prototype undergoes rigorous testing—mechanical, thermal, and functional. Feedback informs necessary modifications, speeding up the iterative cycle.

Stage 5: Final Production and Delivery

Once validated, the project may proceed to small-batch or mass production, utilizing optimized manufacturing techniques suited for end-use products.

Why Choose a China Rapid Prototyping Factory for Your Metal Fabrication Needs?

Choosing the right prototyping partner is vital for product success. Here are compelling reasons why factories like deepmould.net stand out:

- Unmatched Cost Efficiency: Competitive pricing rooted in China’s manufacturing ecosystem.

- High-Quality Standards: Certifications such as ISO 9001 and ISO 13485 ensure consistent quality management.

- Technical Expertise: Skilled engineers who understand complex metallic systems and innovative fabrication methods.

- Comprehensive Service Offering: From design consultation to finishing processes, providing an all-in-one solution.

- Sustainable Practices: Embracing eco-friendly materials and waste minimization strategies.

Emerging Trends in China Rapid Prototyping for Metal Fabricators

1. Integration of AI and Automation

Automation and artificial intelligence streamline production workflows, improve accuracy, and reduce human error, making rapid prototyping faster and more reliable than ever before.

2. Expansion of Metal 3D Printing Capabilities

Metal additive manufacturing is transforming the industry by enabling the creation of ultra-complex, lightweight, and high-performance parts, especially vital for aerospace and high-end automotive components.

3. Eco-Friendly Manufacturing Innovations

Sustainable practices, including recycling metal waste and utilizing environmentally friendly materials, are becoming standard, aligning manufacturing with global green initiatives.

How DeepMould.net Supports Your Business Growth

Deepmould.net stands out with its unwavering commitment to innovation, quality, and customer success. Their comprehensive approach includes:

- Offering tailored prototyping solutions catered to various industry needs.

- Employing cutting-edge technologies like multi-axis CNC machining and metal additive manufacturing.

- Maintaining strict quality control protocols to ensure every prototype meets client specifications.

- Providing rapid turnaround times to accelerate your time-to-market.

- Delivering cost-effective services without sacrificing quality and precision.

Conclusion: The Future of Metal Fabrication and Rapid Prototyping in China

As global manufacturing shifts toward more innovative, efficient, and sustainable practices, china rapid prototyping factory networks like deepmould.net are pivotal in shaping the future. Their expertise in metal fabricators and advanced prototyping technologies empower businesses to innovate rapidly, reduce costs, and stay competitive in an increasingly demanding market.

Whether you are developing a new product, optimizing existing designs, or readying for mass production, partnering with a reliable China-based rapid prototyping factory provides you with the technical expertise, technological edge, and logistical advantages necessary to succeed.

Embrace the future of manufacturing by harnessing the power of rapid prototyping and metal fabrication excellence—your gateway to innovative product development begins with the right manufacturing partner.